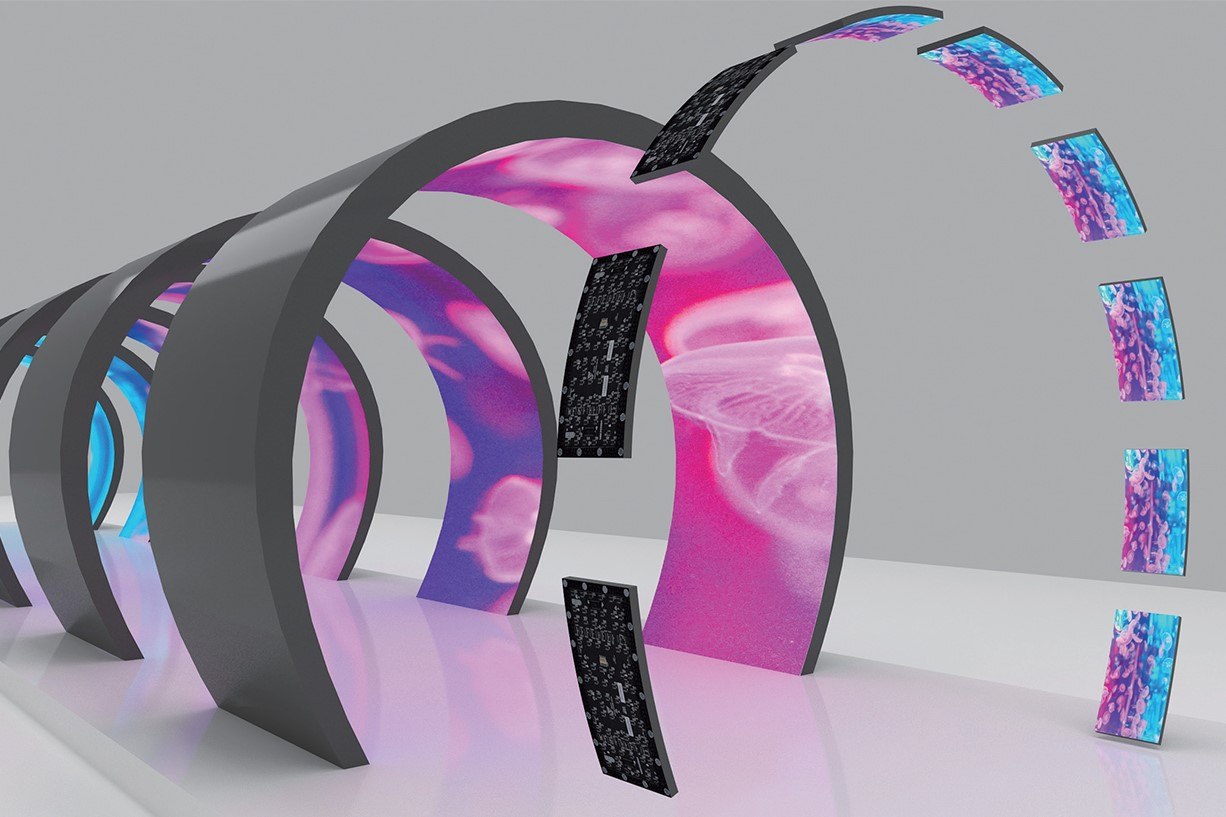

The Role of Magnetic and Soft PCB Technology in Modern Roll-Up LED Displays

Roll-up LED displays have become a defining direction in the flexible display market. Their appeal grows as more commercial environments demand portable, lightweight, and adaptable visual systems. Although the concept looks simple, the engineering behind these flexible screens involves many complex decisions. Magnetic structures and soft PCB technology serve as the backbone of this new generation of bendable LED screens. Their combined influence shapes reliability, image quality, and long-term performance across many environments.

As demand increases, brands and integrators rely on materials and modules that support stable curvature and smooth installation. They also expect these systems to handle daily stress without losing structural accuracy. Therefore, many experts now view magnetic attachment systems and soft PCB engineering as the two key technologies that allow roll-up LED displays to move from idea to reality.

This article explores these technologies in depth. It explains how each engineering choice supports smooth bending, stable pixel alignment, and strong electrical continuity. It also examines the challenges that flexible screens must overcome as commercial installations grow more diverse.

Understanding the Structural Logic Behind Roll-Up LED Displays

A roll-up LED display must function with the same stability as a traditional rigid screen. However, it must also bend repeatedly without damage. This dual requirement creates serious design challenges. A flexible screen must move easily, yet maintain consistent pixel pitch and module alignment. Because of this, engineers must combine mechanical flexibility with reliable electronic pathways.

The foundation begins with the screen’s core structure. Roll-up LED displays use long, narrow modules that stretch along the curve. These modules shift slightly during movement, so their joints must resist stress. Meanwhile, every pixel row must stay aligned, or visual distortion will appear. Even a tiny shift can create noticeable banding across large images.

To prevent distortion, the system depends on soft PCBs that bend without breaking. It also relies on magnetic frames that guide repeated alignment. Each element supports the others. The display functions well only when mechanical stability and electrical integrity remain synchronized. Therefore, engineers design these systems with a strategic balance between rigidity and flexibility.

Soft PCB Technology: The Core Enabler of Smooth Screen Flexibility

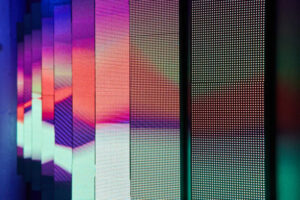

Soft PCBs, sometimes called FPCs, serve as the bloodstream of roll-up LED displays. They carry power and data to every LED pixel while allowing continuous bending. Unlike rigid boards, these flexible substrates use materials that stretch without cracking. Their curves must remain predictable and repeatable during daily use.

Material Choices Define Long-Term Durability

The selection of copper thickness, adhesive layers, and insulation materials has a direct impact on durability. Engineers must choose materials that maintain conductivity while resisting fatigue. Many high-end roll-up LED displays use polymer composites that endure thousands of bend cycles. This endurance supports long-term reliability in rental, exhibition, and mobile environments.

The conductive traces must also follow controlled routing. Sharp angles concentrate stress, so designers create smooth curves along the PCB layout. This approach reduces the risk of micro-cracks that may interrupt electrical flow. Through these decisions, soft PCB design shapes the entire life cycle of the display.

Thermal Management on Flexible Substrates

Heat builds along data lines and LED emitters. Traditional rigid boards disperse thermal energy through thick copper layers and fixed metal backplates. Roll-up LED displays do not enjoy these options. Their flexible nature limits heavy heat-spreading structures, so designers must manage temperature differently.

Engineers often distribute LED drivers more evenly across the board. This prevents hot spots that could weaken the substrate. They also select low-power driver chips and efficient LEDs that generate less heat. These optimizations protect the display’s flexible backbone while supporting stable brightness.

Electrical Continuity Across Moving Sections

Roll-up LED displays may coil, uncoil, and bend many times each day. Because of this constant movement, electrical paths must remain stable across motion zones. Engineers create redundant routing in some designs. This ensures continuous operation even if one micro-path experiences stress. Combined with careful material selection, redundancy increases overall product reliability.

Soft PCBs, therefore, become the hidden strength behind smooth bending and consistent image quality. Their engineering complexity defines how far the display can roll without distortion.

Magnetic Attachment Systems: Quiet Precision for Seamless Assembly

Magnetic structures support the mechanical stability of many roll-up LED displays. They hold modules in place without complex tools and provide reliable, repeatable alignment during installation. As a result, installers can deploy these displays quickly in commercial stages, retail spaces, and mobile events.

Aligning Flexible Modules With Magnetic Precision

Flexible LED modules shift slightly during movement. When these modules attach to a metal base, magnets guide them into their proper positions. This process reduces visible seams and maintains pixel pitch alignment. Because the magnets repeat the same force each time, alignment remains stable even after many installations.

Magnetic layouts also allow curved surfaces to form more naturally. When each module locks to the surface with the same pressure, the entire rolling structure follows a controlled arc. This uniformity supports smooth movement from flat to curved states.

Supporting Repeated Installations With Stable Locking Force

Rental environments often require quick assembly and removal. Traditional screws wear out with repeated use. Magnets avoid this problem. Their locking force remains consistent across many cycles. As a result, roll-up LED displays equipped with magnetic modules can perform long-term rental tasks with minimal degradation.

Magnets also reduce physical stress on the flexible modules. Their soft landing motion protects the soft PCBs during assembly. This enhances durability and reduces maintenance needs.

Enabling Lightweight and Tool-Free Deployment

Magnetic systems remove heavy brackets and mechanical fasteners from the design. This reduces weight, which benefits portable roll-up LED displays. It also shortens installation time and minimizes labor requirements.

These advantages become more significant in large displays. When a screen spans several meters, even small reductions in weight and setup time influence project outcomes.

The Synergy Between Soft PCBs and Magnetic Structures

Soft PCBs and magnetic structures work together to create a flexible yet stable display. Their interaction shapes installation accuracy, image quality, and long-term reliability.

Maintaining Pixel Uniformity During Rolling Motion

Soft PCBs preserve electrical alignment, while magnetic attachments maintain physical alignment. When the display bends, the PCB absorbs tension without shifting pixel placement. When it unrolls, the magnetic frame ensures that modules return to their correct positions. This dual system protects image continuity.

Supporting High-Resolution Applications

Roll-up LED displays now offer finer pixel pitches. Smaller pixels increase stress on solder joints and electrical traces. Soft PCBs reduce this risk by maintaining smooth movement. Meanwhile, magnetic structures hold each module with exact positioning. Together, they support high-resolution imagery in environments that require flexible forms.

Enhancing Portability Without Sacrificing Stability

Portable LED solutions must remain durable during transport. Soft PCBs tolerate vibration, while magnetic modules avoid mechanical fatigue. This combination provides reliable performance even under demanding mobile conditions.

Engineering Challenges That Define the Future of Roll-Up LED Displays

Although soft PCBs and magnetic systems offer many advantages, designers continue to face challenges. These challenges shape future innovation.

Managing Heat in Ultra-Thin Structures

As pixels become denser, heat concentration increases. Flexible displays cannot rely on thick backplates. Engineers must develop new thermal pathways. Innovations may include composite thermal films or conductive silicone layers.

Ensuring Durability at Higher Bending Frequencies

Frequent rolling creates material fatigue. Manufacturers must test thousands of bending cycles before release. Longer life cycles will require improved adhesives, stronger substrates, and optimized PCB routing.

Balancing Brightness With Power Efficiency

High brightness creates heat and stresses power circuits. Many brands explore low-voltage LEDs and efficient driver chips. These solutions reduce energy use and prolong system life.

The future of roll-up LED displays depends on how well engineers solve these issues. Their progress will impact image quality, product lifespan, and adoption across commercial markets.

Applications That Benefit From Magnetic and Soft PCB Advancements

Roll-up LED displays now appear in retail, exhibitions, events, and transport hubs. Their flexible nature opens many new design possibilities.

Advertising Environments

Brands use rolling screens to create dynamic content in tight spaces. The screens curve along walls or wrap around pillars. Soft PCBs allow smooth bending, while magnetic modules support quick installation.

Stage and Event Markets

Rental companies value fast setup. Magnetic structures reduce tools and time. Soft PCBs handle repeated rolling during transport and storage.

Immersive Installations

Designers create organic shapes that traditional screens cannot achieve. Roll-up LED displays adapt to creative structures without extensive metal framing.

Conclusion: Why These Technologies Shape the Next Stage of LED Flexibility

Magnetic systems and soft PCB engineering form the backbone of modern roll-up LED displays. Their synergy provides the flexibility, stability, and reliability required in today’s dynamic visual environments. As commercial expectations rise, these technologies will continue to advance. Their improvements will influence every aspect of installation, maintenance, and screen performance.

The industry now sees roll-up LED displays not as novelty items but as practical tools. Their success depends on engineering foundations that remain hidden yet essential. As soft substrate materials improve and magnetic alignment systems evolve, the market will embrace more complex shapes and flexible designs. These innovations will guide the future of flexible LED technology and support a new era of creative visual applications.

Leave a reply